Solid bodied electric ukulele version 2

- Pete

- Sep 3, 2021

- 5 min read

What's that lurking in the bushes?

The last update a few weeks back saw me making a few practice body to neck joins in an effort to improve the fit and understand the transition from body to neck without wasting one of the bodies I'd started. Whilst this was a useful task, I wasn't fully happy with the results and couldn't get a feel for how it would sit with a full neck and body. So I went to the lockup and found some more timber to make a couple of full test bodies

These two planks turned out to be 50% useable, the darker one is Iroko (which I seem to have a lot of) a useful timber for many things but a bugger to work and not ideal for instruments. The other board turned out to be quarter-sawn light meranti.

I cut a section and split it in half on the table saw since my bandsaw won't resaw a block this wide, unfortunately, It was a bit wasteful on the cut leaving me with a blank that was too thin.

So I found a bit of salvaged mahogany from a desk my brother made for his a-level CDT project, which I glued up into another thin blank to glue together into one thicker body blank with the meranti.

I also found a length of Sapele in the pile to use for necks. It wasn't fully quarter-sawn so for additional stability I split the blank in half, flipped the grain direction and laminated in 3 strips of thin rosewood and pau rosa (offcuts from acoustic ukulele back and side sets).

I also found a couple of fretboard blanks in my stock pile.

Since these were to be test pieces I decided to try a different approach rather than cutting and glueing the scarf joint these neck blanks were left thicker and the headstock angle cut on the chop saw.

I also added a square carbon fibre tube to the centre of the neck for stability, then cut the neck and headstock shape on the CNC.

Before gluing the two body halves together I carved out some weight relief cavities and space for the pickup wiring.

The two halves were then glued together aligned with dowels, and then the body machined on the cnc

I changed the neck pocket design, leaving the neck tenon full width where it enters the body, hopefully making the joint easier to get a clean fit rather than the shoulders of the previous design. The edges of the body were rounded over on the router table.

The neck was rough shaped using a knife, then refined using a Shinto rasp, file and sandpaper.

Next, I started working the neck to body join, initially with the neck dry fitted, the neck pocket was marginally too deep so I added 3 veneers which can be seen in the carved transition. The shaping was done using rasps, files, knife and sandpaper but it was a slow process, a long neck angle grinder with wood disc is what the pros (Pete Howlet at least) use and is a far quicker option.

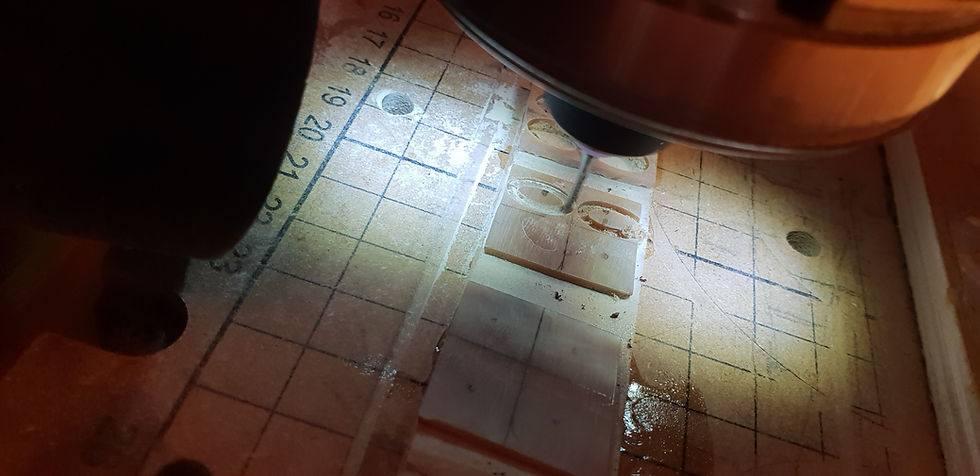

With the neck fitted and transition carved I set up my first fretboard carve using the CNC with a 0.5mm bit. I used a rosewood fretboard blank and decided on small ovals for position markers to be cut from the pink lipped mussel shell blanks.

Frets were cut and the tangs undercut, to fit in the blind pockets, using some modified metal nibblers. The frets were glued and pressed in using a stew mac fret press.

I was slightly worried that my fret pockets were a little wide due to the 0.5mm bit being slightly too big and router bearing runout, so I did some research and decided to prebend the frets and c.a. glue them, in the hope of a decent fit. This turned out to be a bad idea, even with the press I struggled to get the frets seated nicely. However after a lot of work it turned out ok.

Next up, I glue the fretboard onto the neck. Another learning point, in the future I would do this before fitting the neck to the body, but again it went well enough. I also added a faceplate to the head which came from an old pit prop that also claimed to be Meranti but it is very different to the body.

I was going to use one of the ebony bridges that I had previously made, but the colour clashed with the fretboard so I made a new one from matching rosewood.

Then finally, I glued the bridge on, made an ebony saddle and nut, added tuners and strings, wired up the pickup and now have a functional ukulele.

So there we have it, the first complete* Underhill Craft and Customs Ukulele.

It has been grain filled and sanded but hasn't been lacquered yet since I don't have sufficient lacquer left and can't find any Wurth lacquer around at the minute. I figure it will need a bit of fettling in the set up and also the neck profile is a bit wide so I'll add the finish in a couple of weeks once I've got it sorted.

Lots of learning points from this one: the neck join design is better but I need to change the order in which I glue up various stages during the assembly fretboard to neck first, then neck to body. Either I need to go back to manually cutting fret slots or I need to invest in the right size bits to get a better fit without glue for the fret. I'm not sure pre-bending the frets was a good idea (on a non-radiused fretboard, bending them results in the tangs being forced down then sideways helping to stop the tang popping out although in my case it just resulted in not being able to get them fully seated). The fret tang under-cuts were reasonably good with the modified nibblers but needed some filing to remove the last bit of the tang. Cutting inlays worked quite well, but the shell blank needs to be held more securely on the CNC and the shell blank needs to be more regular thickness to better fill the pockets. The bridge design also needs work on the pockets for the string knots since they are slightly too small. There could be more weight reduction in the body and possibly a lighter neck too.

This was only meant to be a rough practice item to rework the neck join, but once it got so far it seemed wrong to ditch it.

I have the next set of wood ready, a block of Sapele (resawn by hand this time, less waste but a whole lot more work), a Sapele neck and a Bubinga top from eBay (on the one in one out principle since I sold some wood last week).

Sound sample to follow next week when it's properly set up (may swap strings too since the Aquila set I fitted feel way too thick).

That's all for now.

Comments